About Us

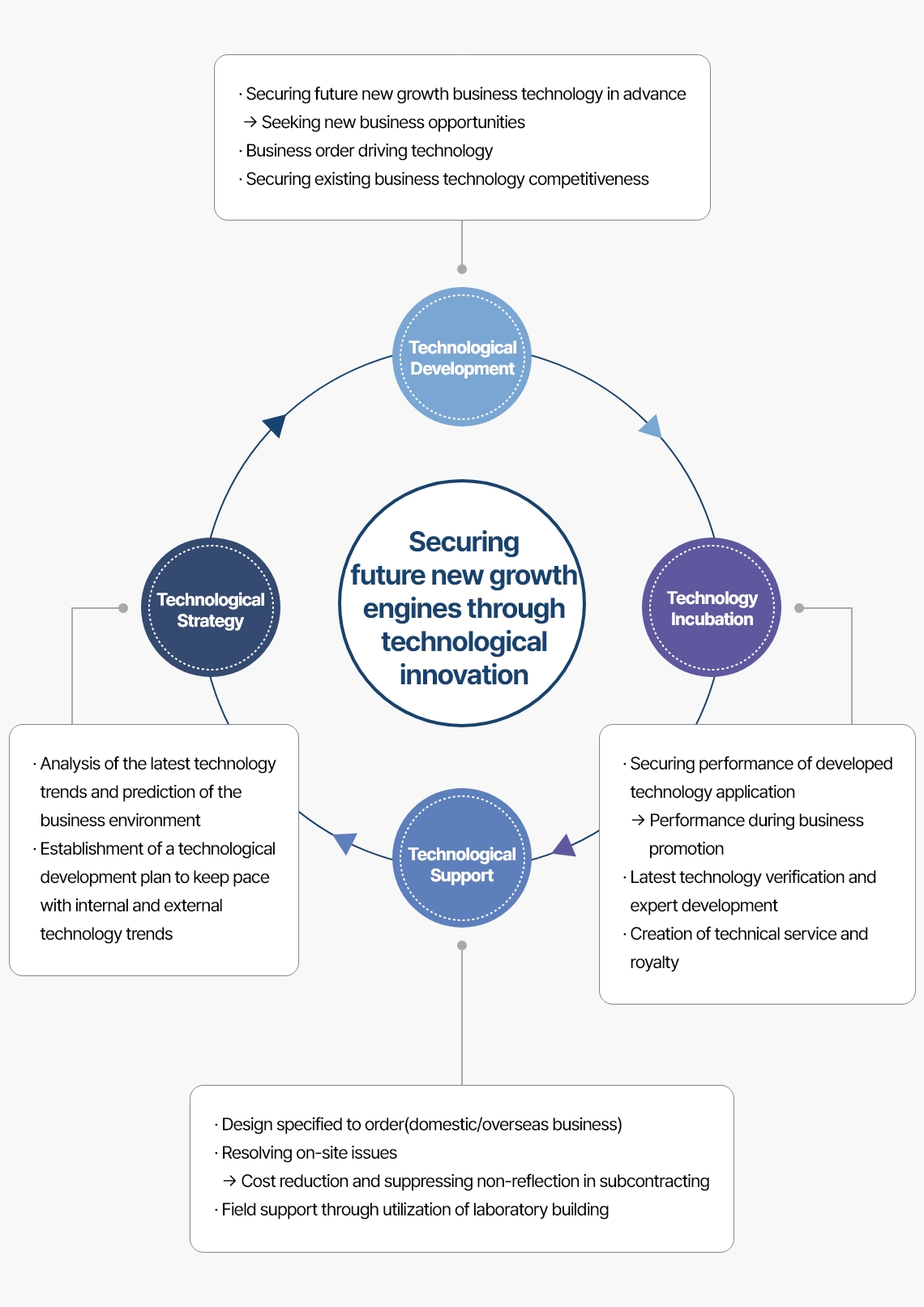

Business Vision

Daewoo E&C opened the Daewoo E&C Institute of Construction Technology(DICT), the first research institute in South Korea's construction industry,

in 1983. Since then, DICT has actively engaged in sector research that maximizes the company's design, construction and development capabilities.

DICT is also carrying out large-scale national, future growth and other projects, contributing to the nation's overall construction technological prowess.

Housing

Off-site construction technology (OSC)

The off-site construction technology employs modular construction

methods, including steel framing and precast concrete, transitioning

the work approach from site-based to factory-centric production.

This shift enhances productivity by reducing construction timelines and costs.

Carbon reduction early strength slag

cement concrete technology

It is a technology that minimizes the use of cement,

a material that emits large amounts of greenhouse gases ( CO2),

and is an eco-friendly, high-quality, low-carbon concrete technology

that can reduce CO2 by up to 54% compared to existing concrete.

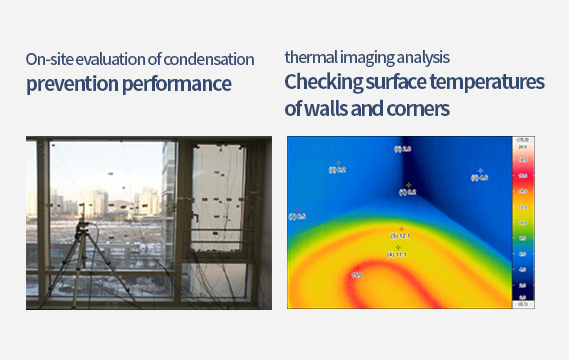

Preventing condensation /

Optimizing building insulation technology

Identifying the causes of condensation on exterior walls,

windows, and in basements, strategies to prevent condensation

formation are proposed.

CIVIL WORKS

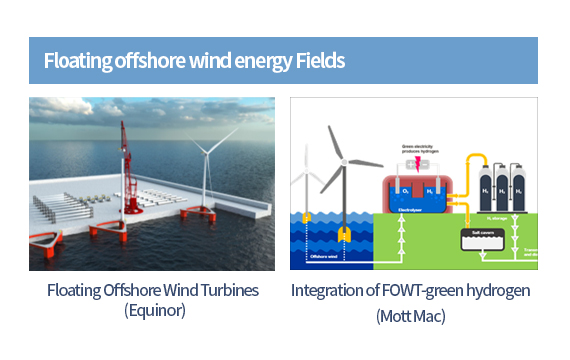

Design Technology for 15MW

Floating Offshore Wind Turbine

Since 2020, a 15MW hybrid floating body(MSPAR) model has been developed

in collaboration with the Dutch design company

Monobase Wind. Currently, we are pursuing the the basic design

certification process for design verification.

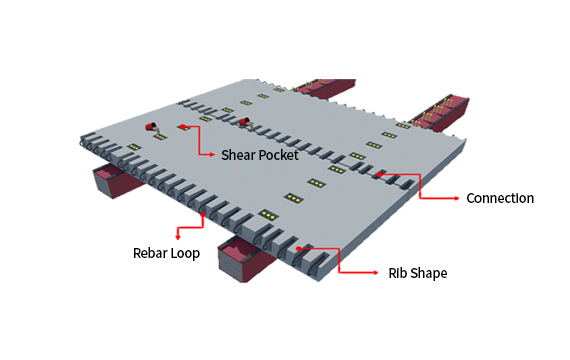

Full Depth Precast Concrete

Bridge Deck System

This system for accelerated bridge construction is able to be

assembled for new construction or replace existing deck,

and the system is favorable for rapid construction and limited site

conditions in overpass bridge construction.

HIT (High-quality Injection Technology)

By reducing cement usage and incorporating eco-friendly grout,

this grouting method helps in minimizing carbon dioxide emissions.

The integration of the automatic injection system adds efficiency and

precision to the process, ensuring consistent quality control.

PLANTS

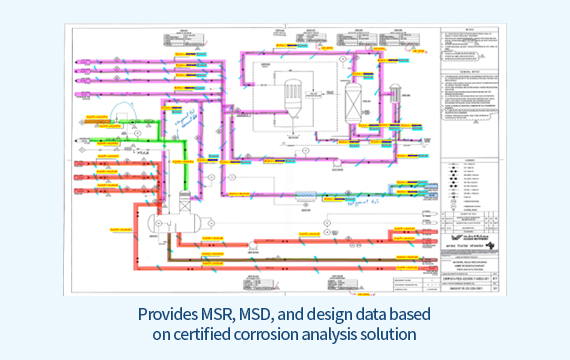

LNG Material Selection &

Corrosion Assessment Technology

The CRA with optimal conditions is selected through basic material

selection guides and simulations considering unit-specific characteristics

(process conditions, corrosion management).

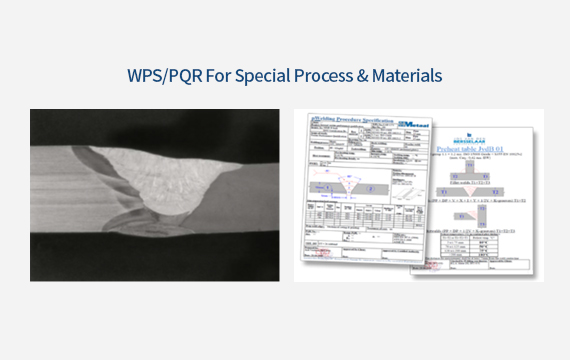

Welding Engineering &

WPS/PQR Development

The engineering and improved technology for welding with recent

improvements are provided. We have welding data for various processes

from domestic/overseas sites, and we are conducting various

verifications such as weldability test.

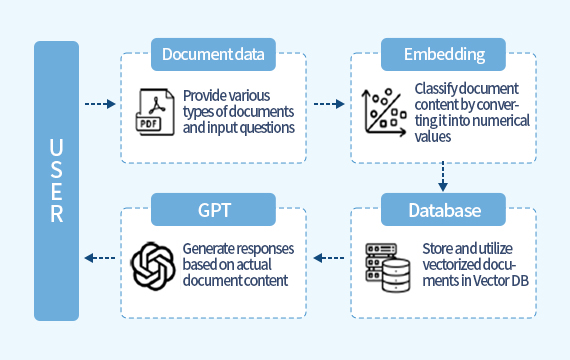

RAG(Retrieval Augmented Generation)

Based Project Document Analysis Technology

Our RAG technology utilizes LLMs to rapidly review and

analyze project documents, meeting diverse stakeholder needs

and maximizing productivity by providing key insights and analysis.